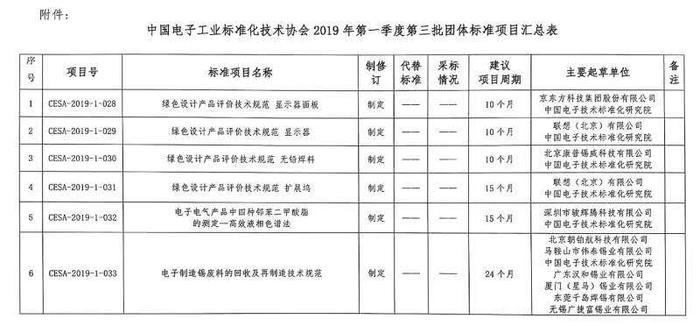

Junhuiteng Technology is dedicated to providing one-stop solutions for factory level RoHS 2.0 instructions. Foxconn Technology Group is a high-tech enterprise specializing in the research and manufacturing of 3C products such as computers, communications, and consumer electronics, with extensive involvement in digital content, automotive components, distribution, cloud computing services, and the development and application of new energy and materials。

On June 4, 2015, the European Union published Directive (EU) 2015/863 in its official bulletin, revising the list of restricted substances (Annex II) for 2011/65/EU (RoHS 2.0). Four phthalates (DEHP, BBP, DBP, and DIBP) were officially included in the list of restricted substances with a limit of 0.1%. This revision shall come into effect on the twentieth day after its publication in the Official Journal of the European Union, and each member state shall translate the directive into its own legislation before December 31, 2016. Execution date is July 22, 2019 (medical equipment and monitoring instruments are July 22, 2021)。

After extensive research and on-site sample evaluation, Foxconn Group's Green Product Center has decided to collaborate with Junhuiteng Technology to establish a model laboratory for testing and promotion of its factories and suppliers. Provide a simple, convenient, and economical solution to address the RoHS 2.0 directive; The LC-2800F from Junhuiteng Technology is a new product specially customized and developed based on the application characteristics of Foxconn Group。

On April 15, 2019, Foxconn Group and Junhuiteng Technology jointly launched the RoHS2.0 directive response one-stop laboratory at Foxconn Group Longhua Park. At 10:28 am, Manager Cao, Ding, Hu from Foxconn Group's Green Management Center, as well as Junhuiteng Technology, Mr. Lei, and representatives from the sales department, unveiled the laboratory plaque;

Foxconn Green Management Center Manager Cao and Junhuiteng Technology jointly unveiled

Showcase a corner of the testing center

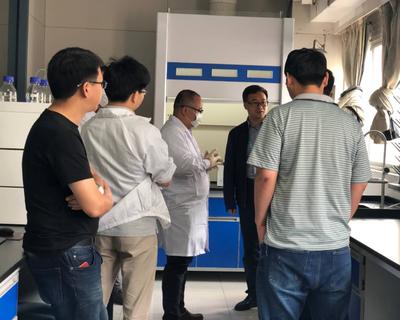

Subsequently, Manager Cao came to the laboratory for guidance, carefully inquired about the usage situation, and conducted in-depth discussions on service related issues;

Manager Cao communicates and answers on-site issues

After the ceremony, Mr. Hu led everyone to visit the South China Testing Center and had an on-site exchange and learning session on various other equipment。

The detection methods for phthalates restricted in RoHS2.0 mainly include gas chromatography (GC, GC-MS) and liquid chromatography (HPLC), such as GB/T22048-2008 "Determination of phthalates plasticizers in polyvinyl chloride plastics for toys and children's products", GB/T21928-2008 "Determination of phthalates in food plastic packaging materials", GB/T28599-2012 "Determination of phthalates in cosmetics". Gas chromatography is prone to contamination by other organic compounds and requires high pre-treatment of the sample. In addition, phthalates have a high boiling point and require high gasification temperature and column temperature, while liquid chromatography has simple pre-treatment, good repeatability, and strong anti pollution ability. There is no high temperature. Therefore, liquid chromatography is more suitable for the detection of phthalates。

Junhuiteng Technology has always focused on providing one-stop solutions for factory level RoHS 2.0, and its cooperation with Foxconn Group has pushed the level of specialization to a new height。